Grillo-Smoking House – is a professional, mobile device for BBQ. The device has the right to register the industrial design PT No. 6787 and the health quality certificate HŻ/D/975/2004.

According to the Act of 30 June 2000. Industrial Property Law (Dz. Ust. nr 49/2002 poz. 508, Dz. Ust. nr 74/2002 poz. 676, amended by Dz. Ust. 108/2002 pos. 945, as amended, Dz. Ust. No. 113/2002 item 983) and the Act of 16.04.1993 on combating unfair competition (Dz. Ust. No. 47/93 item 211 with later changes). All rights related to information taken from this document are reserved in Poland. Copying, distribution, use for professional and utilitarian purposes of the device and providing services, as well as communicating the contents of this document is prohibited.

Those who violate this prohibition are obliged to cover the resulting losses.

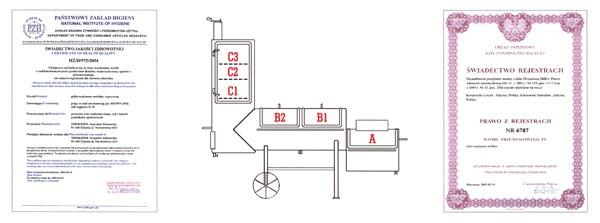

Description of the barbecue Part A- Chamber (hearth – barbecue) : The hearth has a cylindrical shape with different cross-sections depending on the model of the grill. It is made of boiler sheet with a thickness of 4 – 6.2 mm, painted with heat-resistant paint up to 800˚ C – with food approval. On one side, the hearth is connected to the barbecue or bbq. chamber. On the other side, it is finished with a door in which a pane is installed, used to regulate the air supply affecting the temperature. The door is used to support the fuel – wood. In the cylinder, there is a hole in which the flap used to support the wood is fixed, it also helps to light up the barbecue, when the flap is open, the wood lights up without emitting clouds of smoke. On the flap there is a shelf on which you can put the pot or pan. In the middle of the cylinder (hearth) there is a movable grate, made of black bar with a diameter of 16 mm. on which the wood is placed. In the upper part above the wood on two angles it is possible to install a grill grate (made of stainless steel rod ø 6 mm.). This grate can be used for traditional barbecue directly above the heat or for baking potatoes etc. When starting the barbecue in the first phase, a lot of fuel should be added in order to warm up the device and generate heat (it is best to use wood that obtains high temperatures during combustion, e.g. oak, beech, ash), and then use wood that is preferably deciduous alder, beech, or some fruit necessary for proper processing: meat, fish, etc. (see wood characteristics). In a further phase, the amount of wood used for thermal treatment is adjusted according to the needs, depending on the way of smoking: cold, warm or hot.

Part B – Barbecue (bbq) or grill chamber: It has a cylindrical shape with different cross-sections depending on the model. The symmetry axis of the chamber (bbq) is parallel to the symmetry axis of the hearth. It is made of boiler sheet 4 – 6.2 mm thick, painted with heat-resistant paint up to 800˚ C, certified for use in food processing. One or more holes are cut out in the cylinder, in which flaps (movable covers) are mounted. From the inside, in the lower part of the cylinder there is a smoke duct, under the covers, a grate made of stainless steel with a 6 mm thick bar is mounted on the angles. In the covers, holes are prepared for mounting thermometers, important for temperature control in the smoking process and barbecue (bbq). In part B1, closer to chamber A, i.e. the hearth, there is a higher temperature and this part is used for fast heat treatment of products at high temperature (barbecue). In part B2 the temperature is lower. In this part of the chamber during the heat treatment the excess fat drips to the gutters and then flows into a bucket. In this way no carcinogenic compounds from the burnt fat are formed. The best temperature for processing products is in the range of 250°-400° F, i.e. ( 110ºC – 180ºC )

ATTENTION ! Research shows that grilling sausages made from cured meat is very dangerous because at 170ºC nitrosamines are formed in the fat layers of meat, which have a carcinogenic effect, exceeding their dose in food has certain toxicological effects and can lead to food poisoning. That is why the thermometers used in our grill – smokehouse allow to control the temperature of meat processing, thus preventing harmful reactions.

Part C- Smoking chamber or barbecue – (bbq) – Like the two previous parts, it is made of boiler plate 4 to 6.2 mm thick. painted with heat-resistant paint. The chamber has a cylindrical shape and is equipped with a tilting arched door with a thermometer. Vertically axial smoking chamber is permanently connected with horizontally axial parts of the hearth and grill. Inside the smoking chamber there are three levels of round grates made of stainless steel rod – 6 mm thick. The grill has different diameters depending on the model of the barbecue-smoking chamber. The place where the grates are located is called level C1, C2, C3. Due to the greater distance from the hearth (part A), there is a lower temperature at these levels, Products baked in part B, can be moved to part C in order to be smoked with the smoke, which is produced from the wood underlay to the hearth (chamber A). In chamber C, products can be smoked hanging on specially mounted rods on two levels. The best temperature used for smoking products of meat, fish, etc. should be : 50°-250°F i.e. (22ºC – 120ºC) depending on the type of smoking – cold, warm hot.